It may be when I modified the tail to round it out I bumped out the line by accident outside the tolerances.

The modified symbol and the scalloped frame have been assembled without mishap for almost a week now with no signs of impending failure. Would a truly solid circular frame be able to handle the stress? I didn't have one the right size to test with.

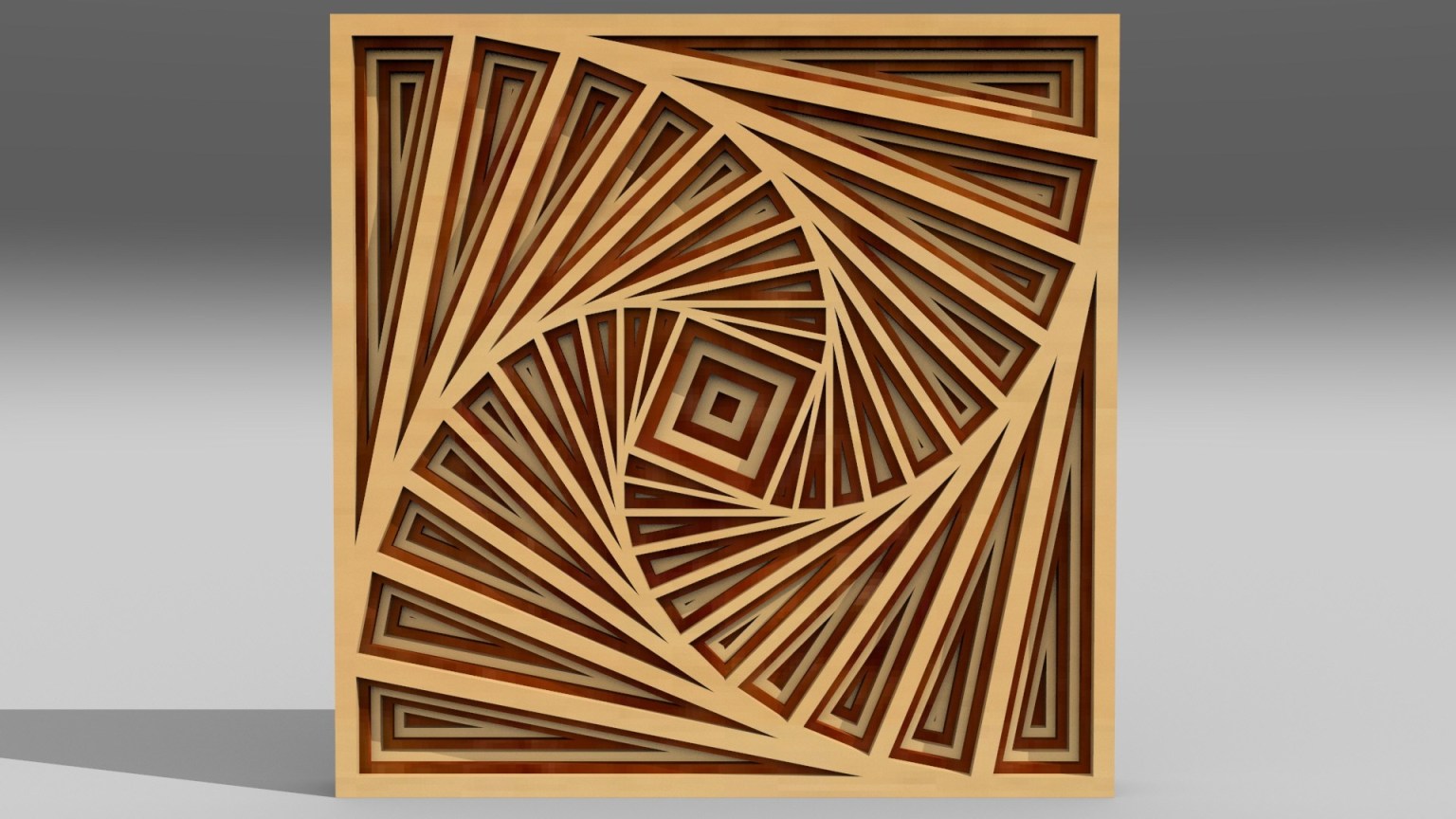

Cut portion of vector inkscape cracked#

Strangely, the modified symbol was able to fit into a "solid" 29.8mm frame for a few seconds, but after a moment, the solid frame cracked at a weak point. The cut pieces fit together snugly with no unsightly gap at the tail either between both commas or between the commas and the frame. The modified symbol fit this scalloped frame where the inner diameter of the circle is 29.8mm (as designed). The modified commas no longer fit together in the design document and in a production situation the designer would probably want to take all the pieces and play with them until an optimal fitting of pieces is created to minimize waste. It might be possible to accomplish the same task with Inset/Outset, but in the File>Inkscape Preferences>Steps>Inset/Outset by dialog, the units seem to be hardcoded to px and we're working with mm here so. The dots use the larger outline and the circular frame uses the smaller inner circle and larger outer circle to achieve the desired cut sizes. My final commas use the larger outline combined with the smaller inner circle. Use the Edit path by nodes tool to remove the undesired path segments. Your outer path is the path to use for an inset object and the inner path is the path to use for a frame object. You should now have 2 paths, but to see that, set Fill to None, Stroke Paint to flat colour (Blue and Alpha to 255 if those got unset), and under Stroke Style set Stroke Width to 0.01mm. Set your Stroke Width to 0.4mm, under the Stroke Style tab. Make sure your Fill and Stroke Dialog is out (Shift+Ctrl+F). Select your objects and convert them to paths. For a better fit all the way around, allowances must be made for the kerf. The inset dots, of course, just fell out. Surprisingly the large curved pieces fit with no visible gaps. In this case the pieces fit after cutting with a gap at the narrowest part of the design. The first sample on the test sheet is a simple design with the interlocking pieces as one graphic to see what would happen. In this example, I will be using as my my test material a 3mm black acrylic which has a kerf of 0.2mm. Of course, different materials and different cutters will have different kerf, you should test. Helpfully, Ponoko has experimented with their various materials and has created a table of how much material is burned away by the cutting laser (kerf) if you are using their services. I warned about the issue of material removed by the cutting process, I decided to test with a sheet in one colour first. A third colour for the frame might be nice. My design calls for pieces cut from 2 different colours to be put together and fit precisely. Not 3D assemblage, but a 2D graphic type design (see below). I wanted to make a laser cut Plexiglas design with interlocking and inset pieces using the Ponoko cutting service.

0 kommentar(er)

0 kommentar(er)